Hydraulic Modeling, the often overlooked factor in treatment plant design

* Note - this material was also presented as an article in the Water Environment Federation's "Influents Magazine" (Focus on Modeling), Spring 2009.

Treatment plant hydraulics is often overlooked as one of the most

important aspects of treatment plant design, especially in plant

upgrade scenarios where retrofitting new equipment or processes

into the existing treatment train will create additional

hydraulic restrictions. Many existing plants already have

a minimal amount of head available for passing peak flows

through the system, which can make plant upgrades even more of a

challenge.

The Bethel Park

Municipal Authority located outside of Pittsburgh, Pennsylvania

faced this exact problem when recently upgrading their trickling

filter wastewater treatment plant. The existing trickling

filter system involved a confusing scheme of recycling flows

between the one trickling filter pump station and both trickling

filters. Rather than the filters operating in series (as

originally designed), they often operated in parallel due to the

poorly designed pump station wet well. A process flow

diagram of the existing treatment plant is shown in Figure I to the right.

In order for the

trickling filters to function as intended in a true series

operation, a separate pump station had to be designed that would

allow flow to be pumped directly to each filter from its own

pumping system. Also included in the design were unique

flow distribution boxes that managed the forward flows to the

filters, return flows from the filters, and provided for the

flexibility of either pump station being able to pump to either

filter should one pump station be off-line. While the

concept behind the flow distribution scenarios was fairly

simple, the hydraulics associated with making the entire design

work was not. Each distribution box has multiple chambers

that direct the flow to its intended location within the

process. Varying floor inverts and weir elevations had to

be established that would ensure that the appropriate amount of

forward flow and return flows were getting to each filter.

Additionally, since the available head throughout the treatment

plant was very limited, the additional head loss created by the

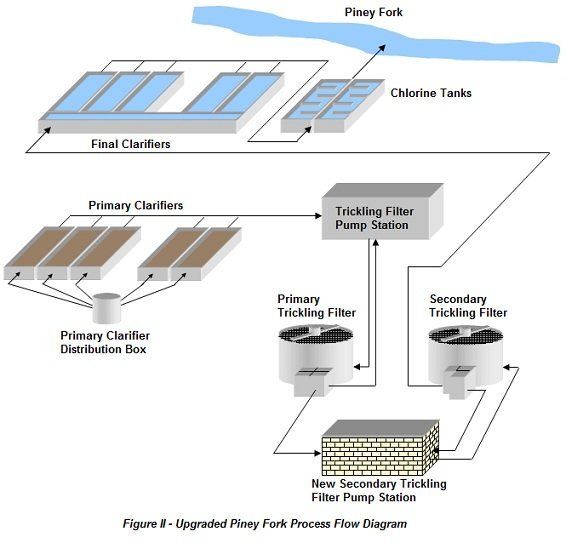

upgraded system had to be minimal. A process flow diagram

of the upgraded treatment plant is shown in Figure II to the right.

With a wide

range of flows possible at the treatment plant (3 MGD - 20 MGD),

hydraulic modeling was determined to be the best solution for

analyzing all of the possible hydraulic scenarios and determine

the design that would be best suited for the hydraulic

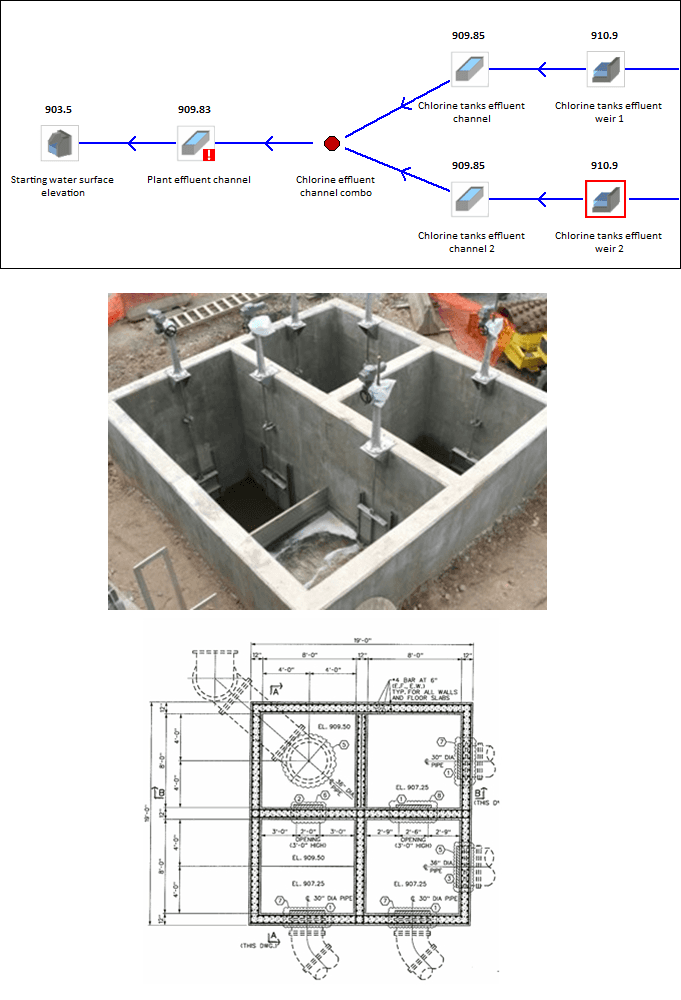

limitations. In order to model the hydraulics for the

Bethel Park plant, Visual Hydraulics was determined to have the

most flexibility and would allow designers to easily change

hydraulic features, return flows, and model the hydraulics over

the range of flows typically experienced at the plant. In

this case, the software was used to model the flow distribution

boxes in terms of box size, invert elevations, and weir

elevations. Through modeling it was also determined that

the best way to control the return flow to each of the trickling

filters was to place gates on the distribution box effluent

lines that would open and close based on the amount of flow

being conveyed to the filters. Under lower flows, the

gates would remain mostly closed, allowing more flow to be

recycled. As the flows in the plant would rise (typically

as the result of rainfall events), the gates would open to allow

more flow to be conveyed as forward flow through the trickling

filters to the secondary clarifiers. This permits the

plant to avoid unnecessarily recycling flows that are mostly

rainwater, which can hurt the biological process. A

diagram of the hydraulic profile created with Visual Hydraulics

for the Piney Fork treatment plant is shown to the right.

Detailed

hydraulic modeling was required to determine how much head loss

should be generated by the distribution box effluent gates to

produce the desired amount of flow being returned to the

filters. This had to be balanced with the amount of flow

to be passed onto the next process in the system. Since

the return flows are conveyed over a weir before being pumped

back to the appropriate trickling filter, the weir elevations

had to be set based on the gate hydraulics as well. Only

hydraulic modeling and the flexibility that a computer generated

model can provide could make this complex analysis as pain free

as possible.

The Piney Fork

plant upgrade project was completed in later summer of 2007.

The plant has received numerous peak flow events that have met

or exceeded the plant capacity of 20 MGD since the plant upgrade

was constructed. The hydraulics of the new trickling

filter system have performed as predicted, and the trickling

filters are producing significantly lower BOD and NH3

concentrations than they have since they were originally placed

into operation over 50 years ago.