Visual Hydraulics Design Recommendations

Visual Hydraulics Design Recommendations:

Treatment

plant hydraulic design considerations:

Flow

conditions to consider: minimum, average, peak, ultimate

Pipes

- Avoid

unnecessary fittings, be as simplistic as possible. One standard 90 degree bend can have much less head

loss than two 45 degree bends:

- Use of a fitting database. Pipe K values can be reported differently in a variety of sources, and the designer needs to take this into consideration.

- Minimum flow velocities of 2 feet per second (0.61 m/s) are usually desired to prevent solids from settling in the pipe.

- Avoid siphons (depressed sewers) where possible, and if siphons are to be used, ensure that flow velocities will be high enough to cleanse the pipe. At least 3 feet per second (0.91 m/s) is the recommended minimum velocity.

- Run parallel pipes along as similar a path as possible. Pipe systems that have pipes laid out with a high degree of variance may affect the upstream hydraulics and contribute to an unequal distribution of flows.

- Understand that the hydraulic analysis of pipes is not an exact science. K values and roughness coefficients (relative roughness "e" value, Hazen-Williams "C" coefficient, etc) are empirical estimates. Pipe age can greatly increase friction losses, as well as the solids content of the flow. Be conservative, but don't "over design".

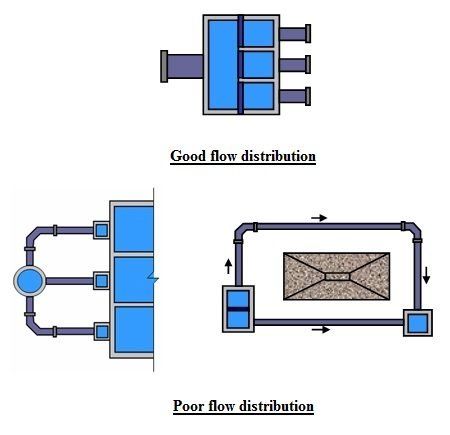

- Use

good flow splitting techniques. If more than one pipe is used to convey flow to

multiple units, equally divide the flow using a flow

distribution structure or other technique. This is especially important for multiple pipes that

do not have the same characteristics, i.e. length and/or

fittings. Less

flow will go through pipes with higher head losses. This may cause a significant variation in the amount

of flow to each unit (see below).

Channels

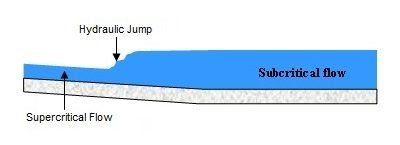

If

possible, keep channel slopes to a minimum. Steeply sloped channels can create high flow

velocities and create unwanted flow scenarios, such as

hydraulic jumps. The

hydraulics of these flow scenarios can be difficult to

predict:

Channels

should maintain a constant cross section wherever possible.

Changes in channel depth or shape can alter flow patterns

which in turn can create unwanted headlosses. These

headlosses may be difficult to analyze.

Channel

networks should distribute flow as equally as possible.

This can be done by flow splitting techniques. Examine the

channel network used to distribute flow to 9 final clarifiers

shown below. Flow is distributed to each clarifier via

channel "reaches", which branch off from the main

distribution channel. Flow will always follow the path of

least resistance or head loss. In the design below, more

flow will go to clarifiers 1, 2, and 3, and the least amount of

flow will go to clarifiers 7, 8, and 9. This is because

the head loss from the main channel entrance to clarifiers 7, 8,

and 9 will be greater than the head loss to clarifiers 1, 2, and

3. Depending on the design, this loss may be fairly

insignificant and there may be virtually equal distribution.

But on long channel runs or other factors such as differing

geometry, this flow distribution anomaly can create hydraulic

issues, especially under higher flows.